Technology

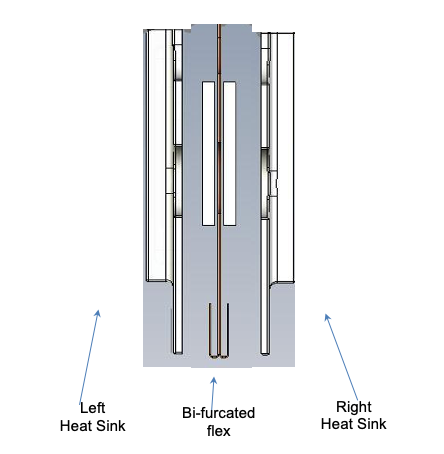

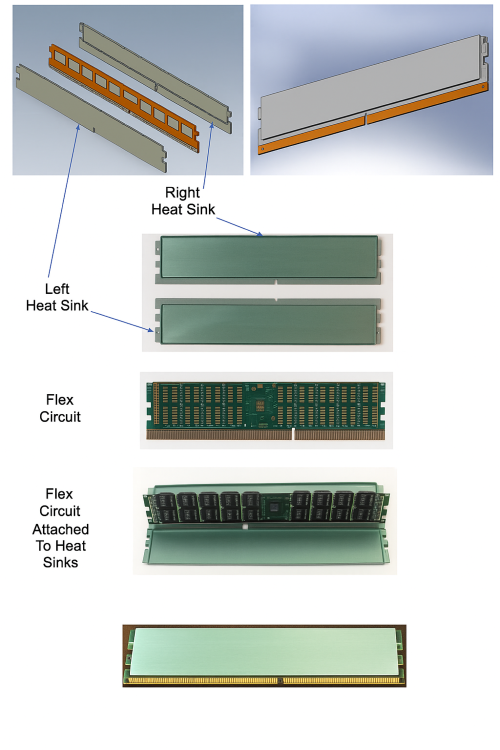

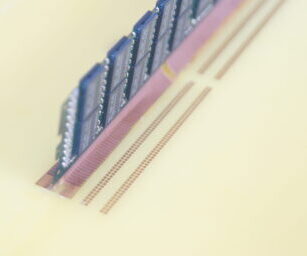

MAT’s Core Flex technology consists of a 4L flex circuit board with 2 internal layers (i.e., layers 2 & 3) being the signal layers. The portion containing the contact pads remains selectively split (bifurcated) apart for mating with external heat spreaders. Each heat spreader is laminated to the bifurcated portion of the flex circuit using a thermo-plastic adhesive. The 2 heat spreaders are then mated together to form a sealed, protective enclosure for the ICs mounted on the flex circuit board. This is particularly helpful for Wafer Level Packaged ICs. MAT’s modular packaging enables ICs to go directly from a wafer to a module form factor without the additional steps of packaging each IC individually, which reduces cost.

Bifurcated flex is bonded to 2 heat spreaders to form an enclosed module with Chips inside the metallic enclosure.

Flexible Circuits For Modular Packaging

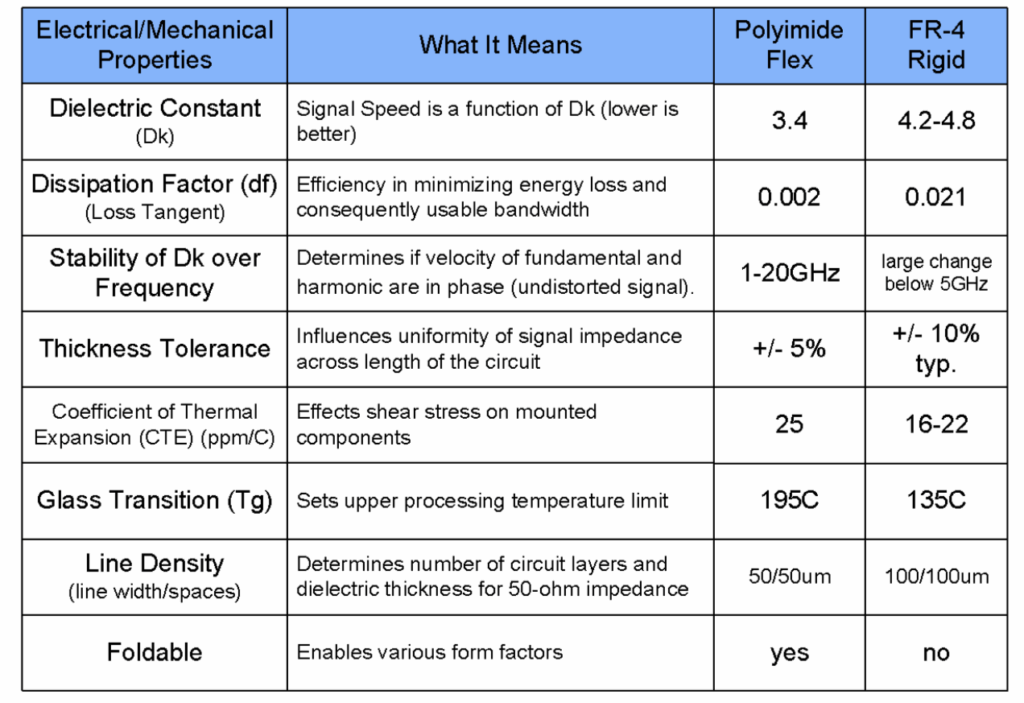

Flexible circuits based on Polyimides benefit from excellent electrical and mechanical properties which translate into superior products for the end user. Polyimides have lower dielectric constants (3.4) compared to their FR4 counterparts (4.5) which translates to higher signal speeds. The dissipation factor (i.e., the loss tangent) of Polyimide Flex Circuits is 1/10th that of FR4-based circuits and therefore leads to minimized energy loss and usable bandwidth. Undistorted signals can be obtained over a broad frequency range (1 – 20GHz), which makes the technology scalable for future needs. The glass transition of these materials is 195C compared to 135C for FR4 (which is more tolerant to thermal excursions). The line density (line width / line space) for Polyimides Flex Circuits is 50/50µm compared to 100/100µm for FR4. The sum total of these attributes makes Polyimides Flexible circuits uniquely suitable for solving modular packaging challenges, including but not limited to: modular thickness reduction, thermal dissipation, and higher signal integrity. An FR4 circuit board containing 12 layers can be designed and fabricated using 4 Layer Polyimide Flex Circuit boards. This results in thinner boards (up to 70% thickness reduction) and enables high heat dissipation (by virtue of the copper clad laminates contained within the layers).

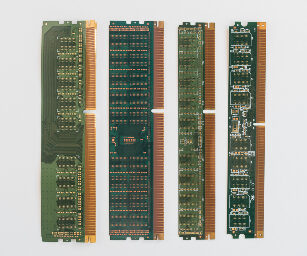

Bifurcated Flexible Circuits Examples

(Standard Height UDIMM, RDIMM & VLP RDIMMs)

Examples of bifurcated flex circuits

Signal layers on the inside of the 4-layer flex circuit are routed to bottom contact pads, which are bifurcated and folded during attachment to two heat spreaders designed for insertion into standard RDIMM sockets.

Examples of pairs of heat spreaders

Examples of fully assembled modules

When laminated to a pair of thin heat spreaders, the bifurcated portions of the flex circuit act as a hinge that enables the module to be opened approximately 300 degrees for easy rework-access to the internal components that are otherwise fully enclosed in a protective enclosure.

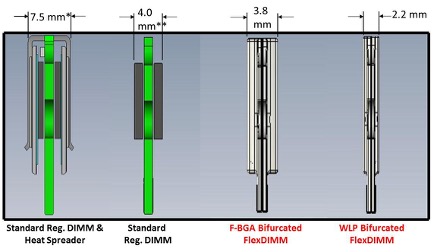

Thickness Reduction By 70%

Significant reduction in thickness is achieved

![resizecom_FireShot Capture 197 - 6-19-17 MAT_Website_Text ZF edits Jim edits Rev D.docx - Google Doc_ - [docs.google.com] EMI Shielding resize](https://matinnovations.11westdesigns.com/wp-content/uploads/2025/11/resizecom_FireShot-Capture-197-6-19-17-MAT_Website_Text-ZF-edits-Jim-edits-Rev-D.docx-Google-Doc_-docs.google.com_.png)

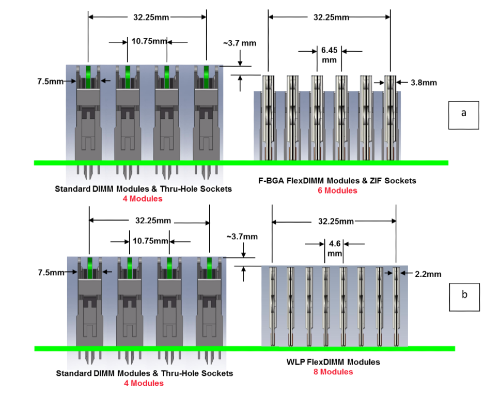

Density Increases By 50% To 100%

Significant increase in density (a- 50% and b- 100%):

Collaborate with the Experts

Contact us to discuss licensing opportunities, design collaboration, or technical consulting.