Direct Connect

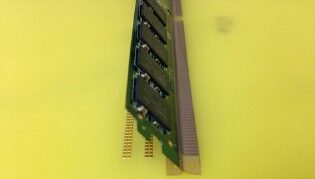

When the bifurcated portions of the flex are bent 90 degrees, the contact pads of the flex module can mate directly with the motherboard. MAT is currently developing multiple connector techniques for directly mating these types of modules to a motherboard.

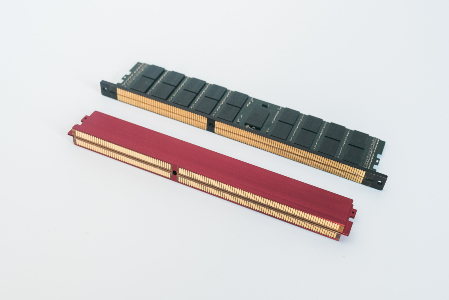

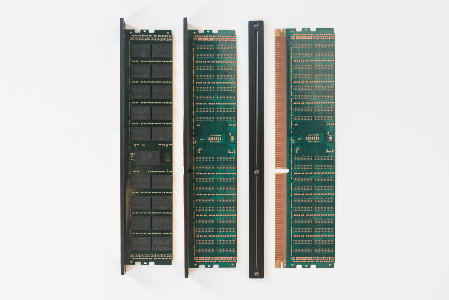

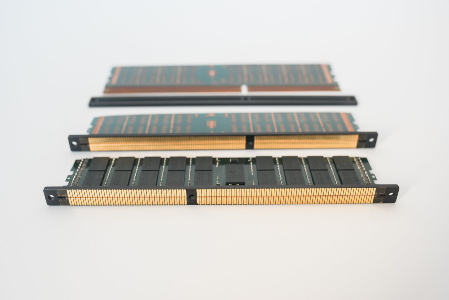

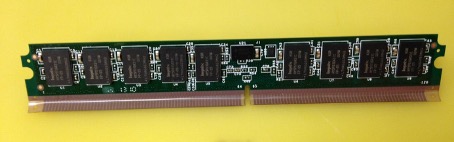

Standard Height 2RX4 RDIMM, with thin aluminum collar (black), and VLP 1RX4 RDIMM, with flanged heat spreaders (red), for direct compression mating to the motherboard.

Low insertion and extraction forces reduce risk and minimize latent failures

Flanged Heat Spreader

Greater module I/O count is required for additional power/ground and signal connections for future memory architectures. But as the pin-count increases for standard friction-wipe contacts for RDIMM sockets, the insertion and extraction forces also increase. The forces required to insert current DDR3 RDIMM modules into standard 240-pin sockets has already led to frequent damage of PCB based RDIMM modules with exposed components. This problem will only become more exacerbated as the number of pins increases to 300+.

MAT feels that a totally new, scalable, mating solution needs to be adopted by the industry for higher I/O module/motherboard interfacing. Our solution is to substitute a compression-type connection between the motherboard and high I/O module. A compression-type contact is not as susceptible to causing damage to the module or its contacts during insertion onto or extraction from the motherboard. In addition, a compression-type interface eliminates the need for through-hole mounting of pinned sockets, freeing up considerable more space for routing traces on the motherboard.

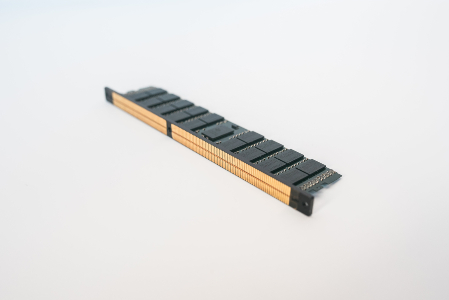

Using the exact same RDIMM flex circuit module developed for mating with a Standard Interface socket, a new “Flanged Heat Spreader” enables the contact pads to be compressed against a planar surface for electrical interface with the motherboard. A variety of compression-type connectors can be inserted between the module and the motherboard pads. For example, Samtec has developed a very low-profile, micro-spring contact (Z-Ray®) perfectly suited for this type of interface: Samtec Z-Ray®.

In addition, thin elastomeric connectors (Zebra Strip), and inexpensive, replaceable, flex-films with compressible, through-hole, contacts can be engineered for this application.

The flanged base on this type of heat spreader design enables the contained memory chips to be oriented as close as feasible to the surface of the motherboard to reduce the length of the signal paths. The internal cavity created by the flanged bottom provides additional room to circulate a cooling fluid for future hyperscale modules. MAT plans to develop fluidic ports that can be compression mated simultaneously when mounting the module to the motherboard using a compression-type socket, which clamps the module to the motherboard.

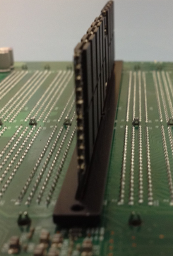

Collar Mounted

Greater module I/O count is required for additional power/ground and signal connections for future memory architectures. But as the pin-count increases for standard friction-wipe contacts for RDIMM sockets, the insertion and extraction forces also increase. The forces required to insert current DDR3 RDIMM modules into standard 240-pin sockets has already led to frequent damage of PCB based RDIMM modules with exposed components. This problem will only become more exacerbated as the number of pins increases to 300+.

An inexpensive, machined and anodized, aluminum collar, with three threaded mating holes and a narrow opening, allows the bifurcated flexible leads on the flex circuit to be inserted through the slit and folded 90 degrees outwardly for attachment to the bottom surface of the collar, similar to the Flanged Heat Spreaders. However, the collar provides a means for supporting the flex module to the motherboard without a need for the metal heat spreaders.

The collar can be mated to the motherboard with three screws inserted through the bottom of the motherboard. The screws clamp the flex circuit leads in electrical contact with pads on the surface of the motherboard. A variety of compression-type interfaces can be used between the flex leads and the motherboard pads, including micro-spring contacts, compressible conductive bumps, pins, or even direct soldering.

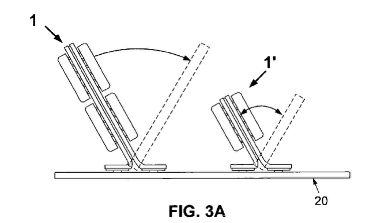

When clamped or soldered to the motherboard, the entire Flex Module can be easily inclined in either direction and held at an acute 45˚ angle with respect to the motherboard to considerably reduce the module’s height.

For direct solder mounting of the collar to the motherboard, the entire module can be easily picked and placed onto screen-printed solder paste bumps and reflow soldered in place without the need for special holding fixtures.

Bare Flex Mounted

Bare flex circuit modules, without an attached collar or heat spreaders, can be directly mated with pads on the motherboard. Flexible circuits are commonly electrically mated to LCD displays using anisotropic conductive adhesive films or pastes that are thermo-compression bonded with programmable heater bar equipment. The same equipment can be used to reflow solder coated pads for direct solder mounting of the flex modules.

Populated Flex Module Mounted Directly To Motherboard

After bonding the flexible leads to the motherboard pads, the modules can easily be inclined in either direction to help reduce overhead height of the modules. This method of bonding the modules directly to the motherboards is a practical solution for reducing costs to a bare minimum when the modules are not intended for future replacement to upgrade to higher memory densities.

Collaborate with the Experts

Contact us to discuss licensing opportunities, design collaboration, or technical consulting.